Heat pumps in more detail.

If you’re considering replacing your current heating and hot water system with a renewable alternative, it’s essential to be aware that this can be a significant investment. In many cases, it involves a partial or complete system upgrade, as heat emitters often (though not always) need to be updated to achieve optimal flow rates. To determine if a heat pump is suitable for your property, you can consult the UK government’s suitability guide. The MCS best practice is here.

The primary types of heat pumps used in the UK include:

- ASHP: Air Source Heat Pumps.

- WSHP: Water Source Heat Pumps.

- GSHP: Ground Source Heat Pumps.

A hybrid system is another option to consider, where a fossil fuel-powered boiler (like gas) works alongside a heat pump. This setup can help meet increased heating demands during the colder winter months while still reducing overall reliance on non-renewable energy sources.

The Basics.

If you’re considering replacing your current heating and hot water system with a renewable alternative, it’s essential to be aware that this can be a significant investment. In many cases, it involves a partial or complete system upgrade, as heat emitters often (though not always) need to be updated to achieve optimal flow rates. To determine if a heat pump is suitable for your property, you can consult the UK government’s suitability guide. The MCS best practice is here.

The primary types of heat pumps used in the UK include:

- ASHP: Air Source Heat Pumps.

- WSHP: Water Source Heat Pumps.

- GSHP: Ground Source Heat Pumps.

A hybrid system is another option to consider, where a fossil fuel-powered boiler (like gas) works alongside a heat pump. This setup can help meet increased heating demands during the colder winter months while still reducing overall reliance on non-renewable energy sources.

Air Source Heat Pump (ASHP) extracts energy from the outdoor air, even at very low temperatures, and converts it into heat. This heat is then distributed throughout the property via a heating system, which may also include hot water circuits.

Water Source Heat Pump (WSHP) extracts energy from a body of water (pond, lake, river) and converts it into heat. This heat is then distributed throughout the property via a heating system, which may also include hot water circuits.

Ground Source Heat Pump (GSHP) extracts energy from the ground below and converts it into heat.

This heat is then distributed throughout the property via a heating system, which may also include hot water circuits.

Heat Absorption, evaporation.

Refrigerant has a low boiling point and absorbs heat.

Compression.

The gaseous refrigerant is then compressed by the heat pump compressor.

Condenser (Heat Exchange)

The hot, compressed refrigerant flows through a heat exchanger, where it transfers its heat to the building’s heating system.

Expansion and Cycle Repetition.

The cooled liquid refrigerant passes through an expansion valve, which lowers its pressure and temperature, making it ready to absorb heat again.

Video from Octopus energy youtube channel.

The Science.

To understand how heat pumps work, we need to cover some basic physics. At a temperature of 0°C (273 K) and a pressure of 1 atmosphere (average sea level pressure), water freezes. This condition is known as “Standard Temperature and Pressure (STP)”. While temperatures can drop below 0°C, the theoretical lowest possible temperature is called absolute zero. At absolute zero (0°K, -273.15°C, or -460°F), there is no molecular motion and no heat energy within the medium. This understanding highlights an important fact: even when it feels freezing outside, the air, water, and ground still contain heat energy. The key is finding a way to extract that heat and transfer it to a usable medium, such as radiators.

This is where refrigerants come into play. Instead of water circulating within the heat pump (like we would have in a gas boiler), a refrigerant (see below) is used.

These refrigerants absorb heat from the outside environment, even at low temperatures, and their temperature increases as they change state. Heat pumps come in three main types: air source, water source, and ground source. Although their setups and installation methods differ, they all operate on the same fundamental principle: transferring heat from one place to another using a refrigerant cycle. Once you grasp the physics of this cycle, understanding how heat pumps function becomes straightforward..ish.

How it works! All heat pumps.

Heat pumps move heat from the selected source into a building through a refrigeration cycle. Whether its air, ground or water they all work on the same principe but with different installation techniques. ASHP use units outside that look like air condition units (they basically are). WSHP use coils or matts submerged in water and GSHP use horizontal loops spread over a open space at a depth of around 2m or vertical loops bored deep at around 100m. The heating side is the same and designed to suit the property and personal preferences. Properties need to be well insulated to reap the full benefits and cost savings. Radiators should ideally be a size and rating to match the system and property requirements. The delta rating of radiators is becoming more important in the system design. Most new builds and retrofitted properties opt for underfloor heating systems, as they naturally run at a lower temperature. MCS blog entry here which explains well.

A radiator’s delta rating, or Delta T, is the difference in temperature between the water circulating in a radiator and the room temperature. It’s calculated by subtracting the average room temperature from the average radiator temperature. For example, if the radiator water temperature is 70°C and the room temperature is 20°C, the Delta T is 50°C

This technology is new to many of us, and it needs to be used a little differently.

Now that you know a bit about Delta T, you can see how important it is to size a heating system correctly for your home. If the heat pump is too small, it will have to work too hard and may struggle to keep up. If it’s too large, it will use more electricity than necessary. The aim is to find the right balance between comfort and running costs — something that’s possible with good design and by using the system the right way.

During the heating season, it’s best to control your home’s temperature rather than demand it. In other words, let the system maintain a steady temperature instead of turning it off and on all the time. It’s more efficient (and cheaper) to let the heat pump gently adjust the temperature up or down.

Most modern systems use outdoor temperature sensors to help with this. These sensors measure the air temperature outside and tell the heat pump how much heat your home is likely to need. On mild days, the system runs at a lower level; when it’s colder, it automatically increases output. This helps your heat pump work in tune with the weather — keeping your home comfortable while using less energy overall.

How to install GSHP from skillbuilder.

How to install WSHP from NHS

How to install ASHP from

Urban Plumbers.

Refrigerants.

This could get long-winded, so below is a brief guide to what is used inside a heatpump.

On the data plate on most heat pumps, you will see what type of refrigerant is used.

Air Source Heat Pumps (ASHPs) use refrigerants to transfer heat from the outside air into your home. The choice of refrigerant affects efficiency, environmental impact (global warming potential, GWP), and performance in cold climates.

Here’s a quick overview of the main refrigerants used in modern ASHPs.

GWP It’s a measure of how much heat a greenhouse gas traps in the atmosphere compared to carbon dioxide (CO₂), CO2 is 1, the lower the GWP, the better for the environment if the refrigerant leaks.

1. R32 (Difluoromethane)

GWP: ~675 (medium)

Efficiency: High

Operating pressure: Moderate

Flammability: Mildly flammable

Common in: Domestic and small commercial ASHPs

Pros:

Excellent energy efficiency (COP)

Lower GWP than R410A

Easy to handle and widely available

Cons:

Mild flammability requires careful handling

Not suitable for all large-scale systems

Most current residential ASHPs from brands like Daikin, Mitsubishi, and Panasonic use R32.

2. R290 (Propane)

GWP: ~3 (very low)

Efficiency: Very high

Operating pressure: Similar to R22

Flammability: High

Common in: New-generation eco-friendly ASHPs, especially in Europe

Pros:

Ultra-low environmental impact

Excellent performance in cold weather

Future-proof under F-gas regulations

Cons:

Highly flammable, strict safety standards required

Limited charge sizes (for safety)

Used in newer models by Vaillant (aroTHERM plus), Viessmann, Intergas, Samsung, and Midea.

3. R744 (CO₂)

GWP: 1

Efficiency: Good for high-temp output

Operating pressure: Very high (~10x higher than R32)

Flammability: Non-flammable

Common in: Hot water heat pumps, commercial units

Pros:

Very low GWP

Excellent for domestic hot water (up to 90°C)

Cons:

Complex system design

Lower space heating efficiency in mild climate

Understanding SCOP and COP.

The Seasonal Coefficient of Performance (SCOP) is a metric used to measure the energy efficiency of a heat pump system over an entire heating season. The coefficient of Performance (COP) only measures efficiency at a single operating point. A more realistic efficiency rating is the SCOP.

How SCOP Works.

SCOP takes into account the following.

- Varying outdoor temperatures throughout the season

- Standby and defrost cycles

- Part-load efficiency (how the system performs at different levels of operation)

SCOP Calculation.

SCOP=Total electrical energy input (kWh) divided by the Total heat energy output (kWh)

A higher SCOP value means better efficiency, meaning the system provides more heat per unit of electricity consumed.

SCOP Ratings & Efficiency.

- SCOP < 2.5 → Low efficiency

- SCOP 3.0 – 4.0 → Moderate efficiency

- SCOP 4.5+ → High efficiency

- SCOP 5.0+ → Very high efficiency

Example.

If a heat pump has a SCOP of 4, it means that for every 1 kWh of electricity consumed, it provides 4 kWh of heating energy, this is why you may hear 400% efficiency.

Controlling heating and hot water.

Many different controls exist for heat pumps and depending on system choices and manufacturers you may need a little help with setting up and understanding. Your installers should leave all the necessary instructions with you and also give you a quick guide. We have some handy links and info on the controls page.

Things to consider. ASHP

- Position. Away from sleeping and noise-sensitive areas. (newer ASHPs are very quiet). Free airflow and not enclosed.

- Condensation removal. Water will come from the unit and can pool. It’s not the same as gas boiler condensate, which can be acidic, so just basic removal to soak away or drain, depending on the manufacturer’s instructions.

- Radiator sizes and pipework. Heat pumps work at lower temperatures, so a bigger surface area, ideally underfloor heating, is beneficial.

- Insulation of property. The better the wall and loft (or room in roof) insulation, the less heat loss.

- Uninsulated pipework. Bathroom supplies and central heating pipework at the plant should all be insulated. All external pipework should be insulated with a class 0 UV protected insulation.

- Maintenance requirements. How regular servicing is required and access requirements.

- Running costs. What is the average yearly cost to run the heat pump! This can be really important, and research and information from your installer is a must.

- Solar matching. As heat pumps operate differently through the seasons, the same goes for solar. If you are having solar PV installed thinking the panels will run the heat pump, then think again. You could try to match the solar generation to the heat pumps output, which could help with running costs.

Things to consider. WSHP and GSHP.

- Position. Either good mass of water near property or parcel of land. Position of subterranean manifolds should be easily accessible for air removal and maintenance.

- Plant room. Space available as heat exchanger and water storage will usually be together.

- Radiator sizes and pipework. Heat pumps work at lower temperatures, so bigger surface area is beneficial, ideally underfloor heating.

- Insulation of property. The better the wall and loft (or room in roof) insulation, the less heat loss.

- Uninsulated pipework. Bathroom supplies and central heating pipework at the plant should all be insulated. All external pipework should be insulated with a class 0 UV protected insulation.

- Maintenance requirements. How regular servicing is required and access requirements.

- Planning permission. Check with your local council if required.

Solar matching. As heat pumps operate differently through the seasons, the same goes for solar. If you are having solar PV installed thinking the panels will run the heat pump, then think again. You could try to match the solar generation to the heat pumps output, which could help with running costs.

The funding.

For any renewable heating project, whether funded privately or through a UK grant scheme, the current best practices, manufacturer’s instructions and relevant building regulations should be strictly adhered to.

If installed on a UK grant scheme then a quality assurance program that certifies small-scale renewable energy systems and installers need to be followed, currently this is called MCS.

Most of the time when applying for renewable funding the installation company usually has the mechanism to set up the funding and this should be explained from the start. You should NOT have to pay anything upfront or post install unless extras are quoted and agreed. These extras could be for instance, larger capacity water heating, radiators as required, location requirements etc.

Currently the funding streams come from the following. These links are directly to Ofgem, UK government and group buying sites. Have a look at the grant area of site for more information.

A insurance backed guarantee is required for ECO measures and is mandatory for those installing insulation through government schemes.

TrustMark registered businesses are also required to provide financial protection to their customers.

Once agreed on funding the installation company will arrange for a property assessment.

The funding process.

If a standalone renewable energy grant is being installed ie. heat pump, solar, biomass etc. then this may not fall under the current PAS and will only need to be MCS certified. unless a ECO 4 package that includes insulation has been developed.

If insulation is being added at the same time as part of ECO funding then the following is applicable.

Property assessment by retrofit assessor.

Detailed assessment to gather information on condition, ventilation, insulation, outcomes, health & safety and EPC data. The retrofit assessor should be someone who has plenty of experience! Assessments can take a few hours depending on complexity of building, condition and proposed insulation/heating improvements.

The retrofit assessor if possible will create a room by room heat-loss calculation and site specific heat pump survey. If the assessor cannot perform this, then the installation company will engage with the property owner to arrange a visit.

The retrofit assessor should look into how the household is made up to gauge energy use and lifestyle. The current insulation levels should also be looked into and improved if needed) prior to install of a heat pump.

This will then get passed onto a retrofit coordinator.

Passed to Retrofit coordinator.

All information should be assessed by a retrofit co-ordinator and system designer, who should scrutinise the data and put a plan together to hopefully protect the homeowner/tenant from failings with the proposed improvements.

A good retrofit coordinator should perform a site visit or visits, as their role has been created to protect you. The work will then enter the designed Installation stage with yours, and the retrofit coordinators approval.

Installation phase.

A plan should be in place post technical assessment, and this should be discussed with the tenant/homeowner. It should be clearly explained, dates and times should be agreed upon for visits from joiners, electricians, and other tradespeople. Ensure all agreements, including timelines and potential problems, are documented in an email or hard copy and that you are happy with proposals. Additionally and if possible take plenty of photos before installation, capturing areas of install including, location of heat pump, location of water storage, areas of insulation (loft etc) and meters.

The installers should also document the same to protect themselves, and the initial assessment should have highlighted areas of concern. A new EPC should be produced post install and can be searched here.

Installation Guide.

The manufacturer’s instructions will highlight any regulations that are required. Currently, all electrical regulations need to be followed and documented, as is the MCS checklists if installed on government scheme. Requirements are that properties are well insulated prior to the installation (fabric first approach) and full heat loss calculations are carried out to provide information to install the system to best practice. If hot water is being heated in storage tanks by the heat pump then steps need to be taken to protect from legionella. Stored hot water systems connected to heat pumps have cycles to heat the water at given times and a given temperature to stop the growth of Legionella bacteria.

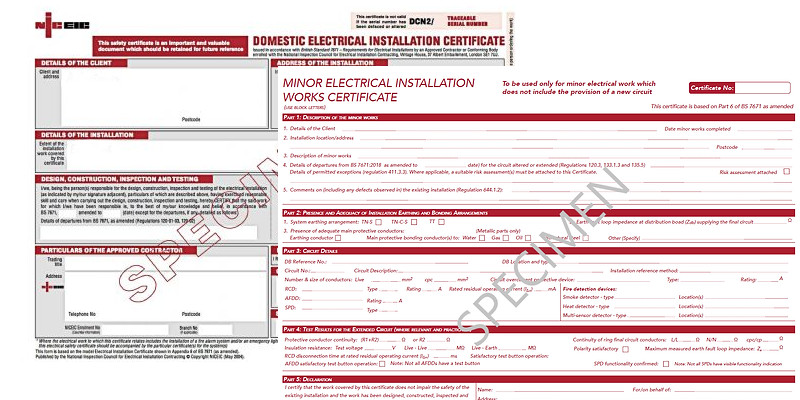

Electrical certificates.

The two types of electrical certificates you will come across as a customer who is having any electrical work as part of installing EEM’s (energy efficient measures)

- Electrical Installation.

- Minor Works Certificate.

Electrical Installation Certificate.

An electrical installation certificate is the type of certificate a customer receives after an electrician has installed one or more new circuits. Other examples include a complete rewire, a replacement consumer unit or an additional consumer unit. Generally, any time electrical work is done at the consumer unit, a new installation certificate will be issued.

Minor Works Certificate.

A minor works certificate is issued after an electrician has made an alteration to an existing circuit. Minor works certificates are often used to certify work such as adding additional sockets to an existing circuit or increasing the number of light fittings in a room. It can also be where a fused spur has been installed for an appliance or boiler connection.