MVHR

The Basics.

MVHR systems combine supply and extraction in a single unit. They remove stale, moisture-filled air from wet areas like kitchens and bathrooms. The heat from this air is recovered through a heat exchanger and then circulated into living spaces. The process can be reversed for cooling when needed.

What is MVHR?

MVHR systems function by preventing the loss of heat during building ventilation.

In traditional ventilation or air conditioning systems, warm, stale air is expelled from the building and released into the atmosphere. Heat recovery increases the efficiency of the heating system by reusing the heat from the air that is being extracted.

A Mechanical Ventilation with Heat Recovery (MVHR) system, equipped with filters, captures heat from the outgoing air and transfers it to the incoming air. Ventilation ducts channel the air through a heat exchanger within the MVHR unit. The incoming and outgoing air streams remain separate and do not mix. MVHR systems can be costly to install and need to be planned, usually around refurbishment or new build, but they are very efficient and the cost saving in energy use is a weighted factor. They roughly cost around £60 per year to run in an average home. If you know the wattage and your electricity cost, then the maths is straightforward if you want to know running costs.

Video from Environvent.

The Pros.

Energy Efficiency. MVHR systems can capture up to 95% of the heat from outgoing air, significantly reducing heating costs.

Improved Indoor Air Quality. Provides a constant supply of fresh, filtered air, enhancing indoor air quality. Effectively removes indoor pollutants such as VOCs, CO2, allergens, and moisture, reducing the risk of respiratory issues and mould growth.

Comfort. Ensures even distribution of air throughout the building, preventing cold drafts and maintaining a consistent indoor temperature.

Environmental Benefits. Lower energy consumption leads to a smaller carbon footprint, contributing to environmental sustainability.

the Cons.

Initial Cost. The initial cost of purchasing and installing an MVHR system can be high, particularly for existing buildings that require retrofitting. Regular maintenance is needed to ensure the system operates efficiently, adding to ongoing costs.

Installation Complexity. Installing MVHR requires a network of ducts throughout the building, which can be challenging and disruptive, especially in retrofits.

Maintenance Needs. The system requires regular maintenance, including filter changes and inspections, to maintain efficiency and air quality.

Potential Noise. While generally quiet, some MVHR units may produce noise that could be noticeable in very quiet environments or if improperly installed.

Space. Depending on the size of the main unit, a dedicated room may be needed.

Installation Guides.

From June 2022 the building regulations (Part F) introduced a more robust commissioning regime with ventilation. All new mechanical ventilation systems should be commissioned, and a copy of the commissioning report should be left on the premises. A link to the BEAMA checklist is here. Building control should be notified unless the installers are members of a self certifying competent person scheme (i.e. NAPIT, NICEIC). MVHR have a much more robust commissioning checklist that includes balancing and filters, this will usually be set out by the manufacturers and building regulations Part F.

Supply Ducts. These carry fresh, filtered air from the MVHR unit to the various rooms in the building. They are usually designed to minimize noise and resistance to airflow.

Extract Ducts. These remove stale air from rooms such as kitchens and bathrooms and channel it back to the MVHR unit for heat recovery.

Return Ducts. These ducts transport the air that has been extracted from the building to the heat exchanger in the MVHR unit, where it will transfer its heat to the incoming fresh air.

Distribution ducts. These are used to distribute the fresh, tempered air throughout the rooms, ensuring even airflow and avoiding drafts.

Grilles and Diffusers. These are installed at the ends of the ducts in the rooms to distribute air evenly and ensure efficient ventilation.

Size right. It’s also very important to get the size of the main unit right, since overly-small units tend to be very noisy.

The extract and supply vents (valves in the industry) in each room also need careful consideration to keep noise to an absolute minimum. This should be referenced to approved document E to comply with noise.

The ducting should be well-insulated to prevent heat loss and should be designed to minimize air leakage and noise. Correct installation and sealing are crucial to ensure the system operates efficiently and to regulat

Tips on controlling moisture and condensation.

Open Windows. Regularly open windows to let fresh air circulate and reduce humidity.

Use Extractor Fans. Turn on extractor fans in bathrooms and kitchens to remove moisture from showers and cooking.

Install Trickle vents. Easy and cheap solution to introduce background ventilation if required.

Check door to floor clearances. This should be around 10 mm from finished floor covering to allow fresh air to circulate from room to room. (fire doors have different regulations)

Avoid drying clothes indoors. Try to dry your clothes outside or in a well-ventilated area.

Use Dehumidifiers. Consider using a dehumidifier in damp areas to reduce moisture levels. If you cannot avoid drying clothes inside, then a dehumidifier can help with the moisture control.

Keep your home at an even temperature. At 18-21 °C, the dew point will very rarely be reached. As we know, affordability can have a huge impact on achieving this.

Use pan lids. Always try to use lids on cooking pans, not only will this reduce moisture, but it makes cooking more energy efficient. If extraction is available when cooking, then try to use it.

Fix leaks. Repair any leaks in your roof, walls, or pipes to prevent dampness.

Insulate Well. Proper insulation helps prevent condensation by keeping your home at a consistent temperature.

Vent Appliances. Ensure dryers and other appliances are vented outside to avoid trapping moisture indoors.

Avoid using portable gas appliances(LPG). Moisture from burning LPG can lead to condensation, which can cause mould and mildew.

Gas and open flued appliances.

If the fabric of the property is being improved and open-flued gas appliances exist, then a gas spillage test should be carried out on each appliance.

Rules exist that give an average unimproved property a certain amount of leakiness (adventitious air) to allow open-flued appliances to operate safely.

This all depends on how much fuel burns over a period of time, for example: 7.5kw/hr, 9kw/hr, 6.9kw/hr. You will see this on the data badge of the appliance (gas rating of an appliance here.). The more fuel used, the more leakiness is needed. Multifuel appliances are treated in roughly the same way but do not come under gas safe legislations. HETAS and building regulations govern multifuel installations and ventilation.

This is the reason combustion ventilation is sometimes needed. This allows the air to be replenished (with an open flued appliance we are burning the oxygen in the room that we use to breathe)

With the introduction of insulation, extraction ventilation should be installed as part of the process, we now have a different factor to add in with gas safety. Extraction fans either pulling or pushing air (PIV) can now effect the performance of the appliance.

Open flued gas appliances should be checked to prove they are not spilling products of combustion into the property. This is verified by performing a spillage test.

Part J states. “Extract fans lower the pressure in a building, which can cause the spillage of combustion products from open-flued appliances. This can occur even if the appliance and the fan are in different rooms”.

Any funded insulation work now includes ventilation upgrades as part of the current PAS, so extract ventilation will be installed. This should have been factored in as part of any ventilation work carried out. A competent person is required to perform spillage tests.

Part B, 8(1) of the Gas Safety (Installation and Use) Regulations 1998 states that no person can make any changes to a premises that contains a gas fitting or storage vessel if the changes would compromise the safety of the fitting or vessel.

This basically means if the fabric of the building (walls, floors, roofs) are being insulated then appliances need to be checked by a suitably competent and qualified person.

PAS 2035 is a comprehensive standard and not a regulation. It was introduced in 2019 as part of the UK government’s commitment to improving energy efficiency in buildings. If work being carried out on a UK funded scheme, then the current PAS and building regulations should be followed.

Part F of the UK Building Regulations, sets out requirements for ventilation in buildings to ensure adequate indoor air quality and prevent issues such as condensation, mould growth, and the build-up of pollutants.

The primary objectives of Part F are to.

Provide Sufficient Ventilation, Control Condensation and remove pollutants.

Click here for more on regulations

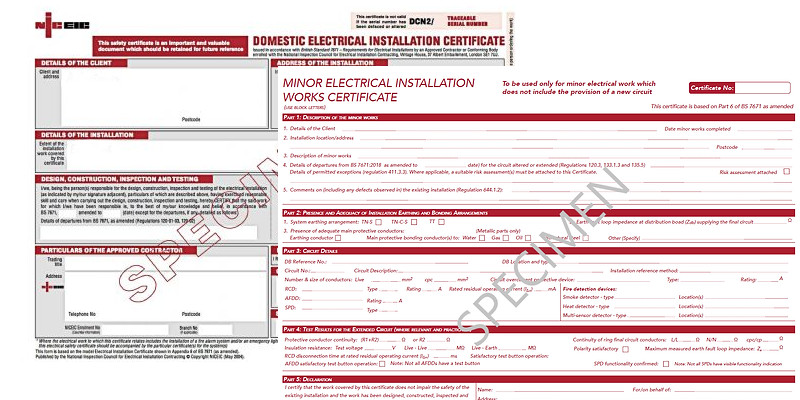

Electrical certificates.

The two types of electrical certificates you will come across as a customer who is having any electrical work as part of installing EEM’s (energy efficient measures)

- Electrical Installation.

- Minor Works Certificate.

Electrical Installation Certificate.

An electrical installation certificate is the type of certificate a customer receives after an electrician has installed one or more new circuits. Other examples include a complete rewire, a replacement consumer unit or an additional consumer unit. Generally, any time electrical work is done at the consumer unit, a new installation certificate will be issued.

Minor Works Certificate.

A minor works certificate is issued after an electrician has made an alteration to an existing circuit. Minor works certificates are often used to certify work such as adding additional sockets to an existing circuit or increasing the number of light fittings in a room. It can also be where a fused spur has been installed for an appliance or boiler connection.