the basics of Extract Ventilation.

The most basic extract ventilation systems are the ones that most of us have in our wet rooms at home. They are usually either manually operated by using a pull cord or light switch, or they are sensor-activated.

This is known as intermittent extract ventilation.

Building Regulation Part F – Covers intermittent extract ventilation (IEV)

What is Intermittent extract ventilation?

This describes a ventilation system the user can control. This control can be via switches, movement sensors or linked services (comes on when room light or shower is activated).

Units are installed in wet rooms (bathroom, kitchen, utility, shower room, WC.) and help with the intermittent removal of moisture or odours. Intermittent extract ventilation (IEV) to the outside should be provided in all the following spaces and be ducted to meet the requirements of the manufacturer. The below are all classed as wet rooms.

Kitchens. Extraction directly to outside, recirculating unit is not an extraction method

Utility rooms. Rooms with water using appliances, washing machines, dishwashers etc.

Bathrooms. Rooms that contain bathing facilities, shower, bath.

Sanitary accommodation. Bathrooms, shower rooms, washrooms, and toilets.

This ventilation needs to be room-specific, and regulations exist to ensure the required extraction rate is met.

IEV is primarily used to remove moisture, odours, and pollutants from specific areas such as kitchens, bathrooms, and utility rooms. These areas tend to produce higher levels of contaminants and humidity. Extractors are activated at set intervals or in response to certain conditions (like high humidity). This can be achieved through timers, humidity sensors or manual controls. If a room contains only a toilet and no windows exist, then the extraction unit should not rely on a moisture sensor only.

IEV units are energy efficient and by operating only when necessary they use less energy compared to continuous ventilation systems.

Now let’s put this together!

When extraction units are used in wet rooms, they expel moist air at a specific rate. To maintain proper airflow, this expelled air must be replaced with a fresh supply inside the property.

This is achieved through recommended measures such as 10 mm door undercuts (ensure compliance if fire doors are involved) and the installation of background ventilation. These features allow fresh air to be drawn in simultaneously, enabling it to circulate throughout the property and replace the indoor moist air.

Improving Indoor Air Quality (IAQ) depends on effective ventilation to eliminate pollutants such as volatile organic compounds (VOCs), carbon monoxide, allergens, dust, and mould spores.

By replacing stale indoor air with fresh outdoor air, ventilation creates a healthier environment and helps reduce respiratory risks.

So why Ventilate.

All this can lead to mould growth, odours, and damage to furniture, structures, and health.

Proper ventilation, moisture control, and regular maintenance are crucial for managing our homes.

In the UK, building regulations define different types of ventilation for this purpose.

Improving Indoor Air Quality.

Improving Indoor Air Quality (IAQ) requires adequate ventilation to remove pollutants like volatile organic compounds (VOCs), carbon monoxide, allergens, dust, and mould spores.

Ventilation exchanges stale indoor air with fresh outdoor air, promoting a healthier environment and reducing respiratory risks.

VOCs, such as formaldehyde, benzene, and ethylene glycol, are present in many everyday products like cleaning supplies, air fresheners, cosmetics, paints, candles, and glues. We also have carbon monoxide, allergens, and dust to contend with.

Regular ventilation helps reduce these pollutants, ensuring cleaner and safer indoor air.

Modern appliances such as dishwashers, clothes dryers, and air fryers add moisture through evaporation and reduce the quality of the air, so adequate controlled ventilation helps maintain the balanced environment and can also become part of the household’s *energy efficiency plan.

*By using controlled ventilation heat loss is reduced as windows do not need to be opened especially in winter.

Installation guide.

Ventilation regulations in the UK are designed to ensure adequate air quality, prevent dampness, and maintain healthy indoor environments. The key regulations and guidance documents include the following:

Building Regulations. (Approved Document F)

This is the primary legal framework governing ventilation in buildings. It applies to new builds and significant refurbishments in England and Wales, including insulation.

The government website has a basic outline and the main points include:

Adequate Ventilation. Provision of natural ventilation (windows, trickle vents etc.) or mechanical systems (e.g., extractor fans).

Ventilation Rates. Specific airflow rates for different spaces, such as bathrooms, kitchens, and living areas.

For example:

Kitchens: 30 litres/second for a cooker hood to outside air, or 60 litres/second for other mechanical ventilation. Bathrooms: 15 litres/second for mechanical extractors. Link here.

The Clean Air Act 1993

Focuses on controlling air pollution. It applies to the design of ventilation systems to ensure they do not release pollutants into the atmosphere. Link here.

BS EN 16798-1:2019

This British Standard provides technical guidance on achieving adequate indoor air quality through design and operation. Link to BSI here.

Additional Guidelines.

CIBSE Guidelines: The Chartered Institution of Building Services Engineers provides detailed guidance on best practices for designing ventilation systems, including natural and mechanical options.

Part L of the Building Regulations: Focuses on energy efficiency. Ventilation systems must balance energy use with adequate air circulation to comply with energy-saving standards.

Damp and Mould Regulations: The last BS standard has been withdrawn, and the UK government has produced guidance.

For regulation links for social housing and landlords, go here.

From June 2022 the building regulations (Part F) introduced a more robust commissioning regime with ventilation. All new mechanical ventilation systems should be commissioned, and a copy of the commissioning report should be left on the premises. A link to the BEAMA checklist is here. Building control should be notified unless the installers are members of a self-certifying competent person scheme (i.e. NAPIT, NICEIC).

Ventilation rate. The minimum ventilation rate required by UK building regulations is within part F and currently set at 0.3 litres per second per square meter of floor area.

Outlet terminal. The outlet terminal should have a free area that’s at least the same as the duct’s cross-sectional area. It should also be designed to prevent rain, insects, and birds from entering the duct. Most units will provide a steady draught when not in use, so flap vent covers are always a good addition.

Flexible ducting. Flexible ducting should be pulled taut and kept to a minimum length, should be supported and installed to manufacture instructions if passes through loft space etc.

Placement. Should be placed as high as practically possible and no less than 400 mm from the ceiling. If placed near a background ventilation point like a trickle vent, then these should be at least 500 mm apart. When installing electrical appliances in a bathroom, zones need to be considered.

Extract ventilation to the outside should be provided in all the following spaces at the following rates.

- Kitchens @ 60 L/s Kitchen cooker hood to outside @ 30 L/s

- Utility rooms @ 30 L/s

- Bathrooms @ 15 L/s

- Sanitary accommodation @ 6 L/s

If a wet room has no external walls, the intermittent extract fan should extract at four air changes per hour, to meet purge regulations.

Gas and open flued appliances.

If the fabric of the property is being improved and open-flued gas appliances exist, then a gas spillage test should be carried out on each appliance by a suitably competent operative.

Rules exist that give an average unimproved property a certain amount of leakiness (adventitious air) to allow open-flued appliances to operate safely.

This all depends on how much fuel burns over a period of time, for example: 7.5kw/hr, 9kw/hr, 6.9kw/hr. You will see this on the data badge of the appliance (gas rating of an appliance here.). The more fuel used, the more leakiness is needed. Multifuel appliances are treated in roughly the same way but do not come under gas safe legislations. HETAS and building regulations govern multifuel installations and ventilation.

This is the reason combustion ventilation is sometimes needed. This allows the air to be replenished (with an open flued appliance we are burning the oxygen in the room that we use to breathe)

With the introduction of insulation, extraction ventilation should be installed as part of the process, we now have a different factor to add in with gas safety. Extraction fans either pulling or pushing air (PIV) can now effect the performance of the appliance.

Open flued gas appliances should be checked to prove they are not spilling products of combustion into the property. This is verified by performing a spillage test.

Part J states. “Extract fans lower the pressure in a building, which can cause the spillage of combustion products from open-flued appliances. This can occur even if the appliance and the fan are in different rooms”.

Any funded insulation work now includes ventilation upgrades as part of the current PAS, so extract ventilation will be installed. This should have been factored in as part of any ventilation work carried out. A competent person is required to perform spillage tests.

Part B, 8(1) of the Gas Safety (Installation and Use) Regulations 1998 states that no person can make any changes to a premises that contains a gas fitting or storage vessel if the changes would compromise the safety of the fitting or vessel.

This basically means if the fabric of the building (walls, floors, roofs) are being insulated then appliances need to be checked by a suitably competent and qualified person.

Regulations.

Part F of the UK Building Regulations, sets out requirements for ventilation in buildings to ensure adequate indoor air quality and prevent issues such as condensation, mould growth, and the build-up of pollutants.

PAS 2035 is a comprehensive standard and not a regulation. It was introduced in 2019 as part of the UK government’s commitment to improving energy efficiency in buildings. If work being carried out on a UK funded scheme then the current PAS should be followed aswel as building regulations.

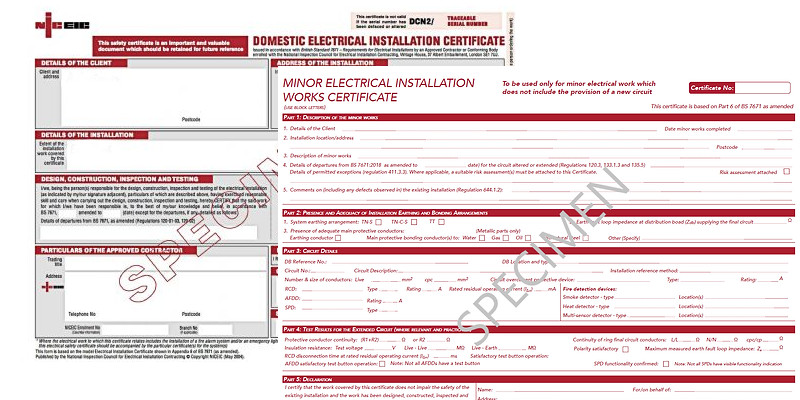

Electrical certificates.

The two types of electrical certificates you will come across as a customer who is having any electrical work as part of installing EEM’s (energy efficient measures)

- Electrical Installation.

- Minor Works Certificate.

Electrical Installation Certificate.

An electrical installation certificate is the type of certificate a customer receives after an electrician has installed one or more new circuits. Other examples include a complete rewire, a replacement consumer unit or an additional consumer unit. Generally, any time electrical work is done at the consumer unit, a new installation certificate will be issued.

Minor Works Certificate.

A minor works certificate is issued after an electrician has made an alteration to an existing circuit. Minor works certificates are often used to certify work such as adding additional sockets to an existing circuit or increasing the number of light fittings in a room. It can also be where a fused spur has been installed for an appliance or boiler connection.