System/regular or conventional Basics.

A combi boiler provides both central heating and hot water directly from the mains, functioning much like a powerful, on-demand kettle.

In contrast, a system or regular boiler works by heating a larger volume of water that is stored in a separate hot water cylinder. This stored hot water can then be supplied to multiple outlets at the same time, for example, when more than one shower or taps are running simultaneously. While this setup provides a consistent flow of hot water to larger households, it does require additional space for the cylinder (and, in the case of a regular boiler, a cold-water storage tank too).

As a result, system and regular boilers are generally more suited to homes with higher hot water demand and ample storage space.

System and regular boiler.

Usually natural gas or LPG. (can be electric, oil or biomass)

System and regular (or conventional) boilers are both heating systems with key differences in how they supply hot water and work with heating systems. Here’s a breakdown:

System Boiler.

Components. System boilers have most of the essential components built-in, like the pump, diverter valves and expansion vessel, meaning they don’t need a separate tank to maintain water pressure. They do, however, require a hot water storage cylinder.

Operation. System boilers heat water and then store it in a hot water cylinder, making it ready for when you require it. The built-in components make them relatively easier and quicker to install compared to regular boilers.

Space. This setup requires less space than a regular boiler because there’s no need for a cold water tank in the loft.

Efficiency. System boilers are energy-efficient and can provide hot water at multiple taps simultaneously, ideal for homes with more than one bathroom.

Regular (Conventional) Boiler.

Components. Regular boilers have fewer components within the unit itself. They require both a hot water cylinder (usually stored in an airing cupboard) and a cold water storage tank, typically located in the loft. Pumps and diverter valves are located externally and need to be designed correctly to prevent circulation problems.

Operation. Cold water is stored in the loft tank, fed to the boiler, and then heated to supply hot water to the cylinder. This design may be more complex to install but can be better suited to homes with an older heating system that already has a water tank setup.

Space. Requires more space overall, due to the need for both a cold water storage tank and a hot water cylinder.

Efficiency. Regular boilers are reliable and can handle large volumes of hot water, ideal for larger homes. However, they may not be as energy-efficient due to heat losses from the cylinder and pipework, which should be fully insulated to improve the efficiency.

Handy notes.

The hot water delivery rate for regular boilers is down to the head of pressure, this means how high up your cold water tank is, as this forces pressure down into the hot water tank. When water is drawn from the taps or shower, this will dictate the hot water flow (this can also depend on pipe diameters). Usually if you require a good power shower then stored hot water can usually supply.

The KW of system and regular boilers is down to the heating demand. Rule of thumb in the trade is treating each radiator as average 1.5kw, so 10 radiators would need a 15KW boiler! Then add 3kw for water heating.

Installation.

For any insulation project, whether funded privately or through a UK grant scheme, the current PAS (Publicly Available Specification), best practices, and relevant building regulations should be strictly adhered to. Once you have engaged an installation company to perform the work, your consumer rights apply regardless of the funding source.

If a funded standalone boiler installation is being installed and is not part of a ECO scheme , then this may not fall under the current PAS and will only need to follow gas safe and manufacturers instructions, unless an ECO package that includes insulation has been developed.

If insulation is being added at the same time as part of ECO funding, then the current PAS needs to be followed.

To achieve effective boiler replacement / install in line with best practices, PAS standards, and building regulations, please review the following installation guidelines:

Installation to be carried out by a competent person. Gas Safe, Oftec, etc.

Boiler to be installed in a safe and accessible area. This is for maintenance and electrical safety, especially in areas that contain bathing facilities (bathrooms).

Magnetic filter fitted. Some boiler manufacturers ask for this as part of warranty. The filter should be fitted to the return pipe on the heating. It is designed to trap rust and debris from the system before it goes through the heat exchanger.

Pipework to be insulated at HW tank and through unheated spaces (lofts, garages etc).

Flue to be accessible via removable panes or hatches. This is a regulation called flues in voids. The entire length of the flue should be able to be inspected.

Hot water tanks to be fully insulated and have temperature control (thermostat). Allows for temperature control of hot water and saves fuel as large mass of heat loss.

A means of interlocking to be present (a room thermostat can introduce interlocking on the boiler). A boiler interlock is a wiring arrangement that prevents a boiler from running when it’s not needed

A means of programming (timer). Able to set on/off, holidays and timed presets. Saves fuel as we have the system on and off as required.

A means to control each heat emitter (thermostatic radiator valves, TRVs). Regulation to allow each room to be individually controlled. Smart radiator thermostats are becoming popular.

A means of safely removing condensation from the boiler (soak away, drain etc). Condensate is acidic but not really dangerous (like lemon juice) but it can damage cement etc over time so it should terminate away from property walls.

External condensate pipework to be insulated with a class 0 insulation and off ground. Condensate pipes can freeze in the winter. Protection using a class 0 insulation (usually black and can be UV protective) prevents the insulation soaking up water and becoming a block of ice! Ideally the manufacturer will state size of condensate pipe to be used, if outside keep off ground and best practice is to terminate indoors. Condensate regulations here.

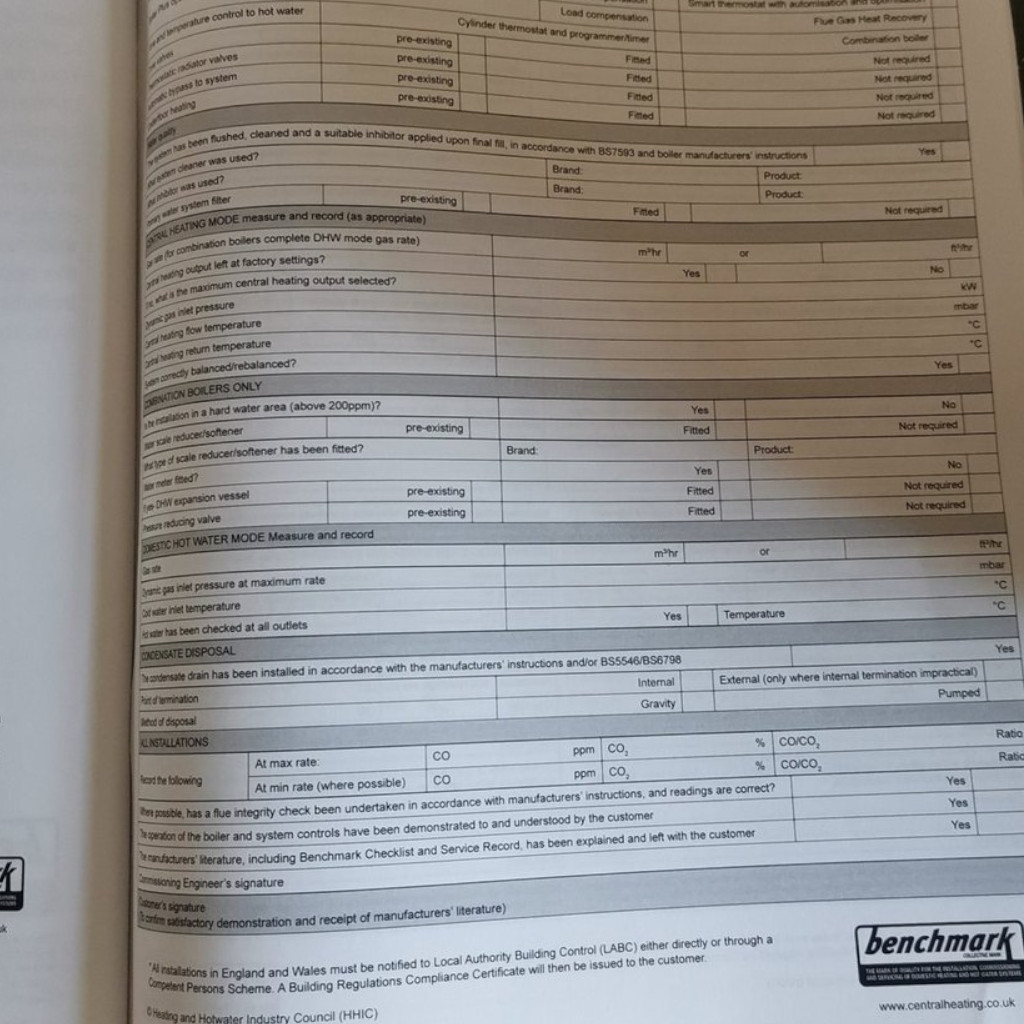

Benchmark to be competed by installer. This is in the manufacturer’s supplied service book. It needs to be filled in by the installer showing installers address, contact number, name, and business. It’s a tick box exercise to show the installer has signed off the installation.

Flues should be at least 300 mm from openings into property (windows, doors etc). This is to stop products of combustion entering the property. A high level flue kit can be used in some circumstances to mitigate distance.

Flues should be over 2m from ground. If not, then a flue guard is needed to protect from damage.

Meeting current building regulations.

Installation Requirements and regulations.

All combustion appliances must be installed by a competent person.

Flues must be clear of openings to prevent products of combustion entering our dwellings. Below is a basic diagram showing flue clearances. Boiler manufacturer installation instructions will show correct clearances for each specific boiler and flueing arrangements (horizontal, vertical). The regulations sections has more information. Here is a link to a some Worcester literature which goes into more depth on flues.

Flue regulations.

All combustion appliances must be installed by a competent person.

Flues must be clear of openings to prevent products of combustion entering our dwellings. Below is a basic diagram showing flue clearances. Boiler manufacturer installation instructions will show correct clearances for each specific boiler and flueing arrangements (horizontal, vertical). The regulations sections has more information.