External Wall Insulation

The Basics.

External wall insulation (EWI) involves adding an insulating layer to the outer surface of a building’s walls to improve thermal performance. It is typically used on solid walls or walls with inadequate insulation. EWI systems usually consist of an insulation material (polystyrene, mineral wool, or rigid foam boards) fixed to the wall, covered by a protective render or cladding.

External wall insulation (EWI) is less disruptive than internal wall insulation (IWI) since most of the work is done outside. However, the property must be in good external condition as panels will be fixed and secured to the substrate of the property.

While EWI can be applied to most wall types, it’s important to consider the specific requirements for each, and to carefully follow best practices and design standards.

EWI installation requires favourable weather due to the curing methods of materials like renders, sealants, and finishes. It’s typically not a DIY project (depending on your skill set), so you’ll likely need professionals to handle the installation.

The retrofit pattern book is a valuable resource for detailing and understanding how professionals should manage risks.

Ensure that your trades people are fully trained in the system being installed, and that valid warranties are provided.

Have a look at the installer page for some handy questions to ask.

Health and safety.

You may need specialist advice from tradespeople and professionals regarding things like,

High amperage cables. External high power cables through walls and building fabric, solar installations.

Nesting. Bees, wasps within walls.

Asbestos. Guttering, downpipes.

As a general rule, high-amperage cables should always be positioned outside the insulation. Some houses may have high-powered cables through the walls feeding garages and outhouses, and these will need to be advised upon by a qualified professional. Some properties also may have been modified with electric supplies routed through the fabric of the building from outside. Have a good look to see if any frequent visitors of bees or wasps are entering the walls.,

Your property may have ladders and possibly scaffolding during installation of energy efficiency measures (EEMs) so it’s crucial for safety guidelines to be in place, warning signs, pavement ramps etc. Contractors should always explain the dangers and inform you of any changes. If you are seeing failings in health and safety, then it will need to be flagged up to the installers on site or supervisors.

If you have close neighbours, then permissions may be needed for access and also approval for works with regard to dust and nuisance during installation. Gas appliances and ventilation requirements should be carefully considered during the work. Address any potential nesting of bats or birds on the property. Some older houses may contain asbestos panels, pipes and guttering, which requires a keen eye and some expertise to identify.

Never disturb anything you are uncertain about; always seek advice from qualified professionals when in doubt.

If any ponds or caged pets are in the proximity to the property, then it’s a good idea to cover during install in case overspill enters the environment. The health and safety section will go into more details of potential hazards.

Pre-installation building inspection requirements Prior to commencing the physical installation of the cavity wall insulation at the location, the Retrofit Installer shall undertake a pre-installation building inspection in accordance with the requirements set out in B1-l2 of Table B.1

Gas and open flued appliances.

If the fabric of the property is being improved and open-flued gas appliances exist, then a gas spillage test should be carried out on each appliance.

Rules exist that give an average unimproved property a certain amount of leakiness (adventitious air) to allow open-flued appliances to operate safely.

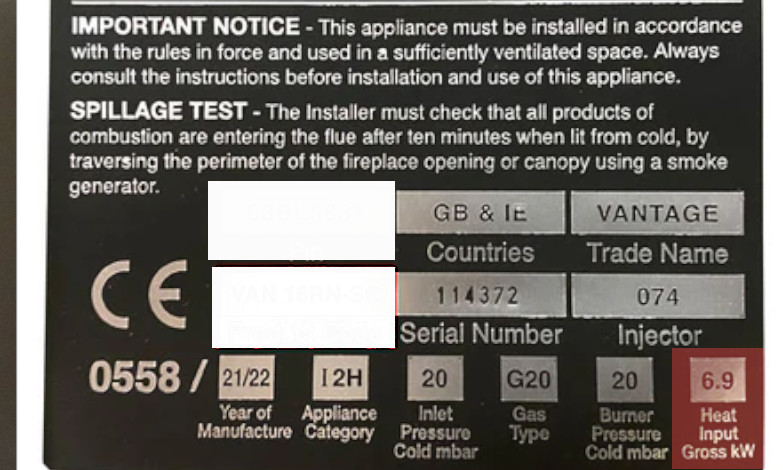

This all depends on how much fuel burns over a period of time, for example: 7.5kw/hr, 9kw/hr, 6.9kw/hr. You will see this on the data badge of the appliance (gas rating of an appliance here.). The more fuel used, the more leakiness is needed. Multifuel appliances are treated in roughly the same way but do not come under gas safe legislations. HETAS and building regulations govern multifuel installations and ventilation.

This is the reason combustion ventilation is sometimes needed. This allows the air to be replenished (with an open flued appliance we are burning the oxygen in the room that we use to breathe)

With the introduction of insulation, extraction ventilation should be installed as part of the process, we now have a different factor to add in with gas safety. Extraction fans either pulling or pushing air (PIV) can now effect the performance of the appliance.

Open flued gas appliances should be checked to prove they are not spilling products of combustion into the property. This is verified by performing a spillage test.

Part J states. “Extract fans lower the pressure in a building, which can cause the spillage of combustion products from open-flued appliances. This can occur even if the appliance and the fan are in different rooms”.

Any funded insulation work now includes ventilation upgrades as part of the current PAS, so extract ventilation will be installed. This should have been factored in as part of any ventilation work carried out. A competent person is required to perform spillage tests.

Part B, 8(1) of the Gas Safety (Installation and Use) Regulations 1998 states that no person can make any changes to a premises that contains a gas fitting or storage vessel if the changes would compromise the safety of the fitting or vessel.

This basically means if the fabric of the building (walls, floors, roofs) are being insulated then appliances need to be checked by a suitably competent and qualified person.

Installation project.

For any insulation or heating project funded through a UK grant scheme, the current PAS (Publicly Available Specification), best practices, and relevant building regulations should be strictly adhered to. The works should be guaranteed and warranted as part of the current PAS standards, MCS or protected by consumer law which can be a little bit daunting in this area, especially for the privately funded installations. A good guide is here.

Privately funded projects will decide on how to install and what guidelines to follow to suit budget and personal achievements.

A Pre-installation building inspection should be performed on either privately funded or grant funded installations. This should highlight any potential areas of concern and the property’s suitability for the proposed installation.

The current PAS requires Installers to undertake a pre-installation building inspection by the requirements set out in B1-l2 of Table B.1

EWI insulation.

Best practice document here.

Correct background ventilation. *All rooms with the installation of trickle vents or wall vents if required

Correct door undercuts. *Undercuts to internal doors allow the free movement of air around the property to allow airflow around the property.

*Testing of the background ventilation pre-installation may allow the installed measure(s) to move forward without the need for door undercuts or trickle vents installed.

Correct extract ventilation in wet rooms. Kitchens, bathroom, WC, and utility rooms are all wet rooms.

If extraction exists, then checks need to be carried out by referencing manufacture’s data or performing an anemometer (testing apparatus) test to confirm extraction rates are being met. If using Positive Input Ventilation (PIV) with EWI the air tightness needs to addressed. If we are improving the air tightness (fewer drafts) of the property, then thought has to be given how the PIV will force the stale air out!

Dmev extraction in wet rooms and background ventilation may be required.

Meeting current building regulations and best practices. Not only just the current PAS.

Electrical cables. High-powered cables from consumer units, etc, need to be address within the insulation and possibly derated or moved to a different location.

Awkward areas and how they will be treated.Retrofit pattern book, a resource to guide you through detailing.

Chimneys. If in use, then do not insulate. If redundant and can be proven to be capped and vented then they will need to follow the latest best practices and guidelines which may allow to be insulated with non-flammable materials.

Asbestos materials. Around boilers, pipe lagging, around fuse boxes, the H&S section has more information.

Existing ventilation. Re-routed or extended as required.

Flueing. On combustion appliances, seek the expertise of a gas safe engineer. Potential for thermal bridging if boiler flues are not extended and designed around the insulation.

Cable, satellite, and telephone services. Service boxes may need extending and suppliers may need to be contacted (Sky, Virgin, etc). Fixings may need to be installed pre or post install for lighting, media delivery, CCTV etc. A good site to get an idea is swifix.

Solar. Inverters and cables may need to be moved if positioned on an external wall.

Insurance. You may need to inform insurance company.

Fire regulations. EWI adds to the envelope of the property, so escape routes and access routes may need to be addressed.

Storage. Safe and dry storage of insulating materials during work.

Damp. Confirming damp course has not been breached.

Neighbours. In some situations access to neighbour’s property is required and permission may be required if neighbouring properties are not being insulated.

Wall Composition and Dew Points.

The makeup of the wall must be carefully analysed to determine the appropriate EWI system.

Dew points. (the temperature at which condensation forms) must be considered to prevent condensation within the wall structure.

Damp Courses. Essential for preventing rising damp. If integrated with the EWI system (insulating below damp course) the correct products should be specified to maintain moisture control.

Overhangs and Water Run-offs. Overhangs (e.g. verge trims, window sills) and proper water run-offs are crucial for protecting the EWI from water ingress and wall staining. Ensure that water is directed away from the insulation layer to maintain its effectiveness and longevity.

Sealing. Angles, especially around door and window frames, need to be in line with best practice and system design. Failings in seals can be unsightly and hamper the prevention of water ingress, leading to failure. Standard sealants should not be used as they will fail over time.

The funding Process.

Application for funding.

This could come through your local council, word of mouth, or door-to-door enquiries. Current funding options are listed here. In most cases, when applying for an insulation or heating grant, the installation company will handle the setup of funding, and this process should be explained from the beginning.

You should NOT be asked to pay anything upfront or after installation, unless additional services have been quoted and agreed upon. These extras could include extensive wall pointing, repairing of water services (gutters etc) and brickwork.

Background and extract ventilation if required should be included as part of the installation requirements and covered by the funding.

An insurance backed guarantee is required for ECO measures and is mandatory for those installing insulation through government schemes.

TrustMark registered businesses are also required to provide financial protection to their customers.

Once agreed on funding, the installation company should appoint a retrofit coordinator who will arrange for a property assessment.

Property assessment by retrofit assessor.

Detailed assessment to gather information on condition, ventilation, outcomes, health & safety and EPC data. The retrofit assessor should be someone who has plenty of experience! Assessments can take a few hours depending on complexity of building, condition and proposed insulation/heating improvements.

The retrofit assessor should look into lifestyles and energy use, this is to model energy use as not all households are the same. They should visually examine the damp proof course around the property and drill a hole at each elevation. They may put a camera (borescope) into the wall (if cavity) to record the condition. These holes should always be filled before the assessor leaves. Orientation and area should be taken into account for wind driven rain and coastal locations. Areas of access and storage should always be discussed, and also time frames.

The Assessor will take lots of photographs to allow the retrofit co-ordinator and the proposed installers to see the whole picture of what needs to be completed to comply with current PAS.

This will then get compiled and made available to the retrofit coordinator.

Passed to retrofit coordinator.

A retrofit coordinator should carefully assess all information, thoroughly reviewing data, to create a plan that safeguards the homeowner or tenant from potential issues with the proposed improvements. An effective retrofit coordinator should conduct a site visit if they determine the installation deems it necessary, as their role is designed to protect you. Once you and the coordinator approve, the project will proceed to the installation stage.

Installation phase.

In accordance with PAS standards, adhering to health and safety protocols and meeting ventilation requirements is crucial and must be clearly communicated. It is important to schedule and confirm dates and times for visits from all tradespeople in advance. All agreements, including timelines and any potential challenges, should be documented in writing, either via email or as a hard copy.

Whenever possible, take ample date-stamped photographs of the property prior to installation. Focus on key areas such as walls, pointing, gutters, and the surrounding environment. Installers should also thoroughly document these areas, particularly if the initial assessment has highlighted any concerns, to ensure they are protected and potential disputes are avoided.

A good video from EON is here to show you the process.

Post Installation and handover. With all work carried out on funded schemes, a handover procedure exists. The retrofit coordinator and installation company will know the funding mechanism (ECO, GBIS etc) and can advise on the handover procedure. The occupants should be asked to sign the works off. Some examples are within the funding section. Hopefully by having some of the knowledge and references this site provides, you will be able to gauge if the work is completed to the required regulations. The standard of the work is really down to the occupier’s perception!

Monitoring. Technical monitoring may also be carried out, and contractor and installer inspections may be performed by the installation company. More details in the technical monitoring section.

Installation approach.

We typically have two ways (and several products) to add External Wall Insulation (EWI), depending on the type of property. Some properties are designed to allow the passage of moisture from inside to outside and vice versa, while others are not. Different approaches are required, and since all walls are not the same, their makeup must be considered in relation to dew points, etc. Damp courses and ventilation are also very important. The process for installing is the same in most cases, and the following is a rough guide to prevent failings.

External wall insulation is a crucial part of improving the energy efficiency of a building. It helps in reducing heat loss through walls and can significantly lower energy bills. There are several types of External wall insulation, each with its own characteristics and suitable applications:

Vapour-Permeable. (Breathable) Systems.

Description. Designed for properties that allow moisture to pass from inside to outside and vice versa. These systems use materials that are vapour-permeable, enabling the building to ‘breathe’.

Materials.

Mineral wool.

Wood fibre boards.

Breathable renders and finishes.

Advantages.

Helps prevent moisture build-up within the walls.

Reduces the risk of mould and dampness.

Suitable for older buildings or those with solid walls.

Considerations.

Careful attention to dew points to avoid condensation issues.

Requires appropriate finishes to maintain breathability.

Vapor-Resistant (Non-Breathable) Systems.

Description. Designed for properties that do not allow moisture to pass through the walls. These systems use materials that are vapor-resistant, preventing moisture from penetrating the insulation layer.

Materials.

Expanded polystyrene (EPS).

Extruded polystyrene (XPS).

Non-breathable renders and finishes.

Advantages.

Excellent thermal performance.

Suitable for modern buildings or well-sealed structures.

Considerations.

Proper detailing to prevent moisture ingress, especially at joints and penetrations.

Effective damp proof courses and water run-offs are critical to avoid water-related issues.

The system (the insulation product and design) should be installed onto a clean and robust substrate, correct fixings to system design should be used. Rainwater services and surface mounted items should be removed. A full starter track should be present with no gaps to prevent vermin nesting and damage to the EWI system. The starter track should be positioned at damp course level, so no lower than 150mm. The EWI can go below damp course to ground level if system and best practices are followed using the right products. The system should be installed in the correct pattern and lines disrupted vertically. Correct meshes and reinforcement at weak areas around window and door corners etc.

A working damp course at 150mm from ground should be addressed in line with the system design, no work should proceed without a damp course in place. Verge trims have to be installed to current standards or rooflines extended.

Windows have to have a regulation run-off of currently 40mm. Render application needs to be of minimum and maximum thickness depending on product. But ideally at least 12.5mm thick.

Walls.

Types of Wall Construction.

UK homes are typically classified into three different types of wall construction:

- Solid Wall

- Cavity Wall

- Non-Standard Construction (System-Built)

Identifying the type of construction is essential for determining the best approach to installing EWI insulation and controlling moisture. External wall insulation can be installed to most wall types including cavity, but best practices and adhering to system design is a must to prevent potential failure.

EWI on a Solid Wall (traditional)

Characteristics of a solid wall.

Usually found in homes built before the 1920s.

No cavity between the walls.

Construction pattern (Flemish, English, common).

Can vary in thickness from single brick at 150mm to stone up to 500mm or more!.

The only vents visible in the walls will be vents to rooms and combustion.

Conclusion.

Selecting the right type of External Wall Insulation depends on the property’s design and moisture management needs. Vapour-permeable systems are ideal for older, breathable walls, while vapor-resistant systems work best for modern, sealed buildings. Always consider factors like wall composition, dew points, damp courses, overhangs, water run-offs, and ventilation to ensure an effective and durable insulation solution.

EWI on a Cavity Wall

Characteristics.

Common in homes built from the 1920s onwards.

Consists of two parallel walls (inner and outer leaves) with a gap (cavity) in between.

Originally, the cavity was designed to prevent moisture penetration, not for insulation.

Visible cavity air bricks, If these have silicon or have been cemented, then possibly the walls have had cavity wall insulation.

Insulation Approach.

EWI is a crucial part of improving the energy efficiency of a building. It helps in reducing heat loss through walls and can significantly lower energy bills. There are several types of insulation, each with its own characteristics and suitable applications:

The insulation products, procedures for EWI on a cavity wall can be found above in the traditional built section as the only difference is that a cavity exists which should be filled and not left empty to control the dew point

EWI on a System built.

Characteristics.

Non-standard build.

Can be poured concrete, blocks, steel frame or mixture.

Also known as prefabricated, loft space may show signs of steel framing and concrete loft floor.

Insulation Approach.

EWI is a crucial part of improving the energy efficiency of a building, It helps in reducing heat loss through walls and can significantly lower energy bills. There are several types of internal wall insulation, each with its own characteristics and suitable applications:

The insulation products, procedures for EWI on a system built property can be varied depending on system design. Some buildings are of a steel or concrete structure, and fixing methods can differ from traditional methods.

Good to know.

Each type of rigid insulation has its specific advantages and disadvantages. When choosing insulation, please be aware strict rules exist within building regulations on fire safety. Some products have different fire and smoke ratings, so please check with system designers, product literature and regulations.

Installation guides and best practices.

Below you will find links to UK regulations and other useful information. These links are to third party websites, and we cannot guarantee the validity or safety of the following sites. If you find any broken links or issues, we would love to know. Please read our disclaimer. Contact us here for issues.

Energy saving trust guide.

Pas 2035

Pas 2030

Part A – Structure

Part B – Fire safety

Part C – Site preparation and resistance to contaminants and moisture

Part D – Toxic substances

Part E – Resistance to sound

Part F – Ventilation

Part G – Sanitation, hot water safety and water efficiency

Part H – Drainage and waste disposal

Part J – Combustion appliances and fuel storage systems

Part K – Protection from falling, collision and impact

Part L – Conservation of fuel and power

Part M – Access to and use of buildings

Part O – Overheating

Part P – Electrical safety

Part Q – Security in dwellings

Part R – Infrastructure for electronic communications

Part S – Infrastructure for charging electric vehicles

Part T – Toilet accommodation

Regulation 7 – Materials and workmanship

The Gas Safety (Installation and Use) Regulations, 1998

MCS (microgeneration certification scheme)

Electrical standards